О Zyfra Heat Treatment

Программный комплекс для обеспечения автоматизации процессов на уровне оперативного производственного управления и обеспечивающий предоставление технологу и оператору линии термообработки рекомендаций по заданию технологических параметров с целью получения необходимых механических свойств продукции с учетом исходных данных (химический состав, масса, толщина и др.).

Продукт в первую очередь предназначен для автоматизации процесса на производстве с линиями проходных печей непрерывного действия.

ТОП-10 ЛУЧШИХ ПРОЕКТОВ на IoT World Congress в Барселоне

Данные и отчетность

Накопление и анализ производственных данных. Насраиваемые отчеты для инженеров и менеджеров.

Оптимизация

Выбор оптимального режима для процесса термообработки партий с возможностью оперативного внесения корректировок в режиме реального времени.

Контроль себестоимости

Снижение издержек производства за счет увеличения целевых показателей процесса.

2%ПОВЫШЕНИЕ КАЧЕСТВА

5%РОСТ ПРОДУКТИВНОСТИ

10%СОКРАЩЕНИЕ ИЗДЕРЖЕК

Подробнее об особенностях решения

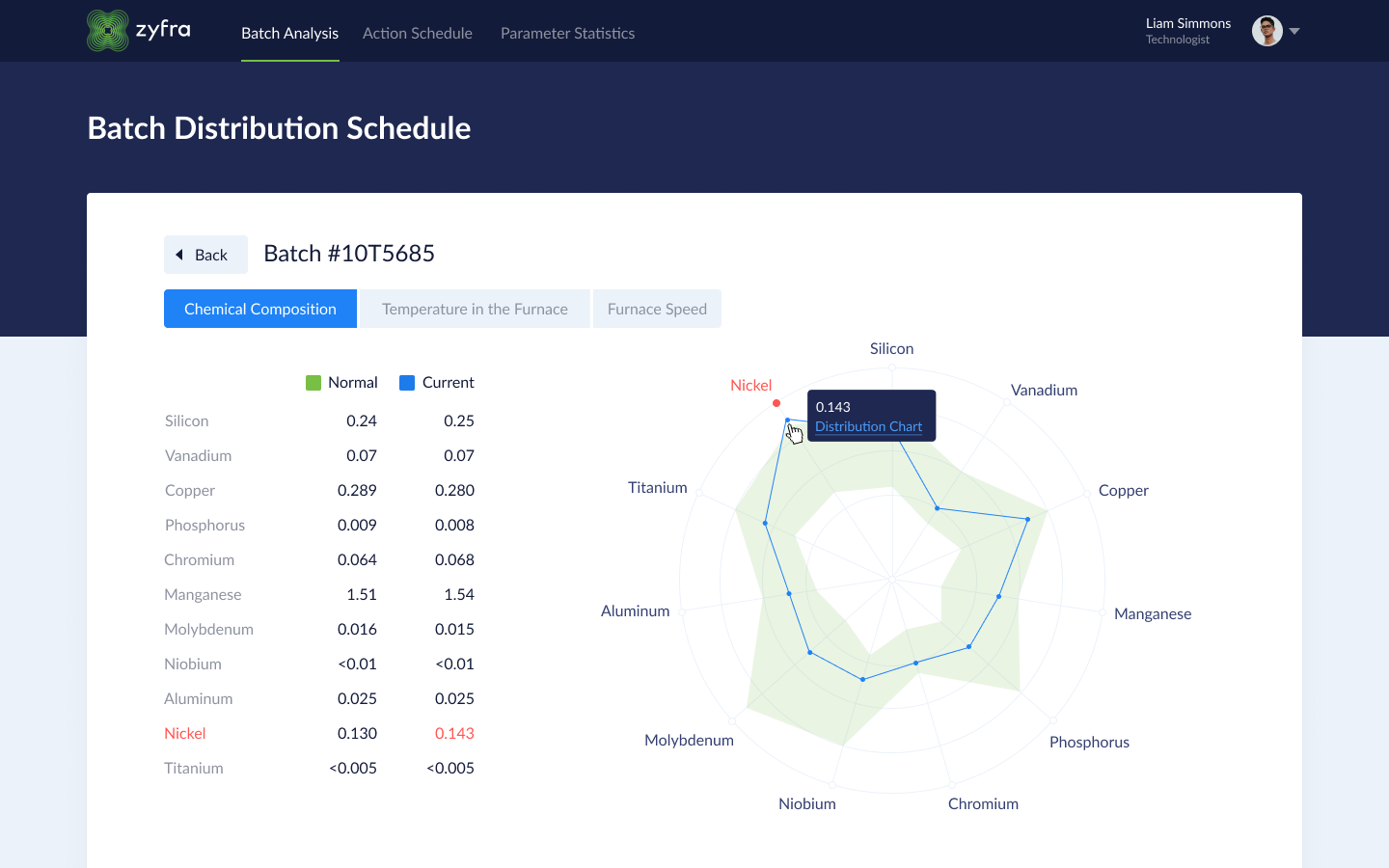

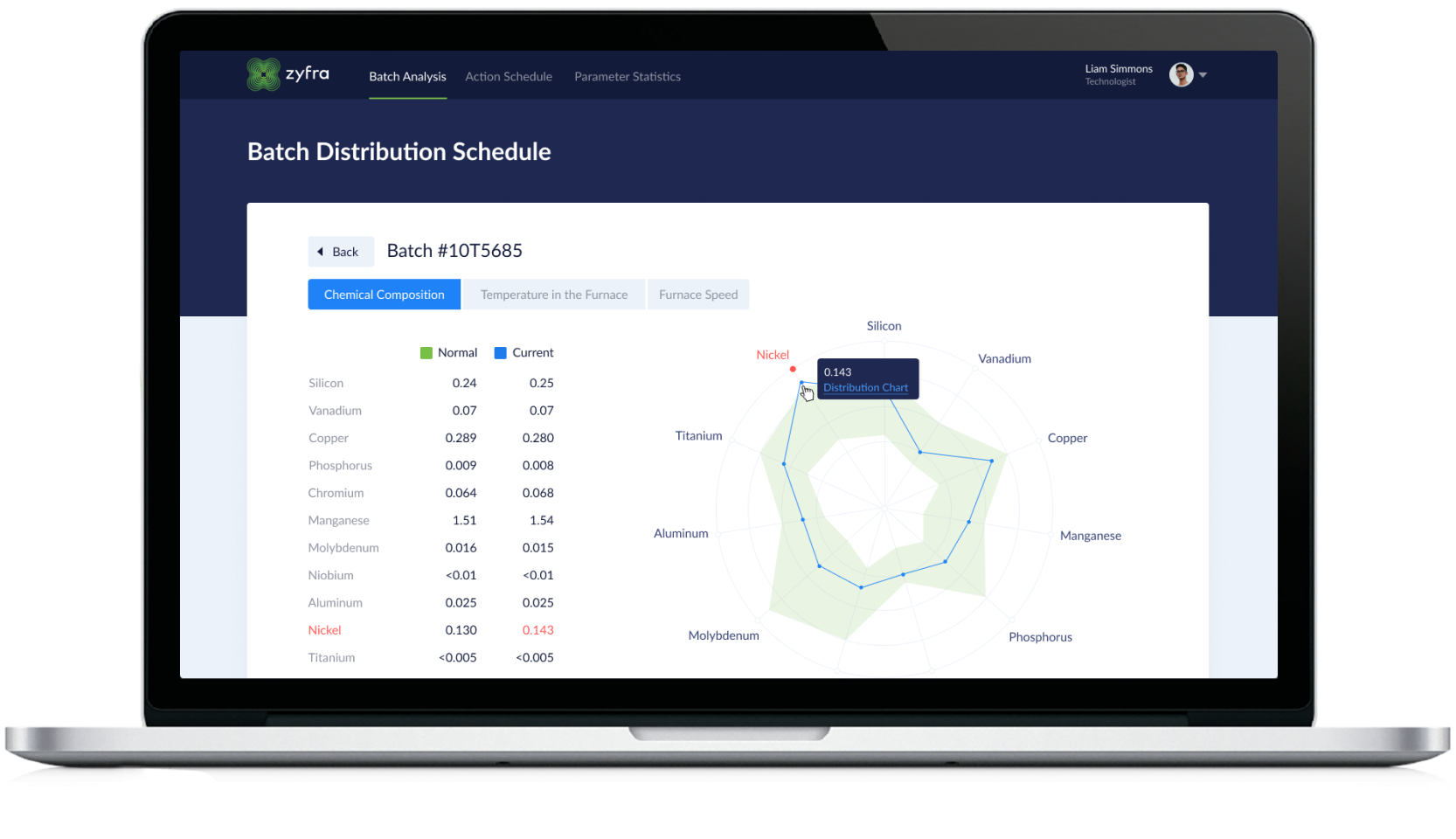

Cоздание режимной карты термообработки в автоматическом режиме

На основе исходных данных из смежных корпоративных информационных систем Zyfra Heat Treatment создает режимную карту термообработки в автоматическом режиме, что позволяет снизить нагрузку на технологический персонал.

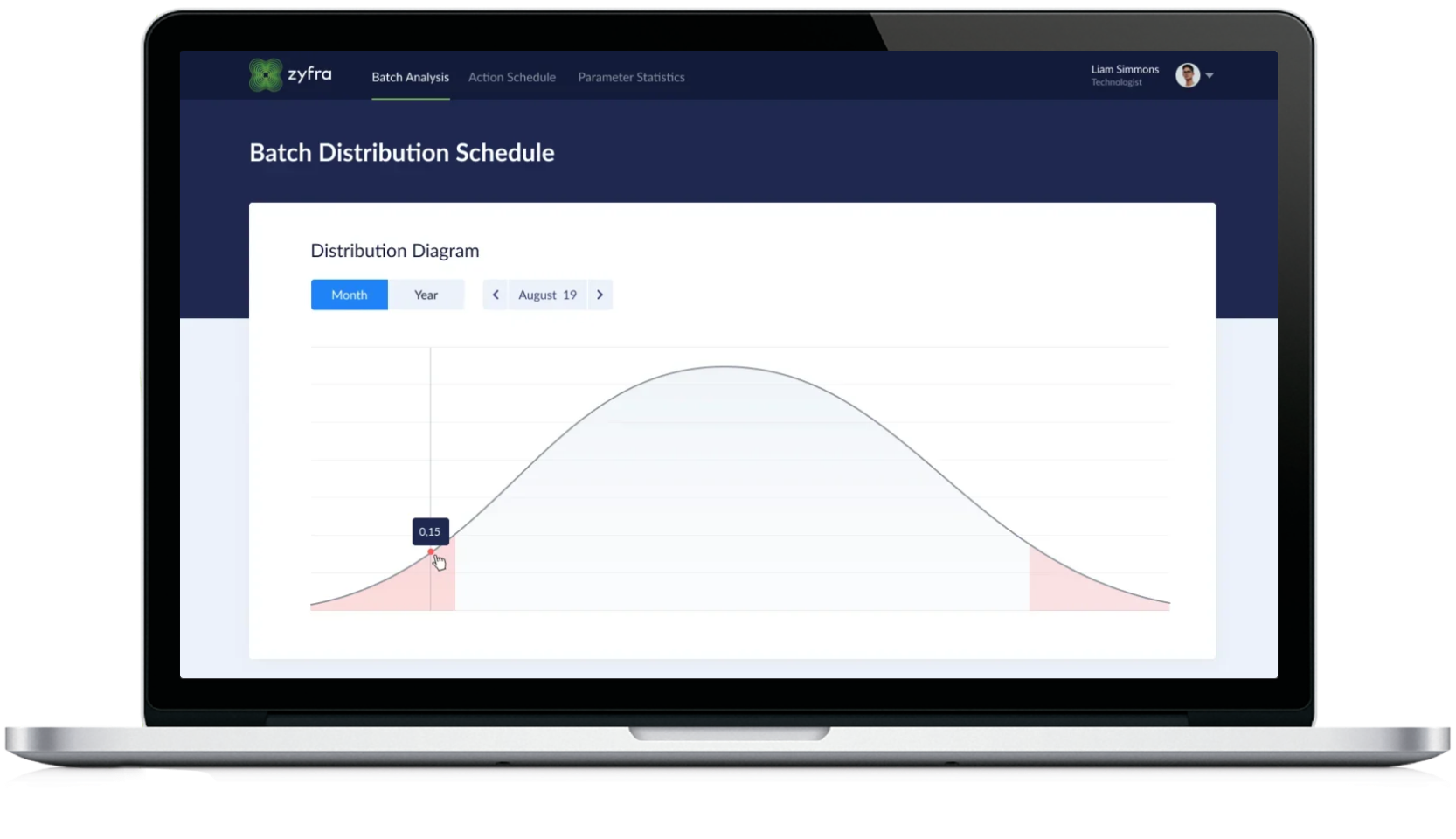

Поддержка принятия решений в реальном времени

Система автоматизации контролирует и выдает рекомендации оптимальной температуры и времени пребывания в печах и закалочном устройстве так, чтобы поддерживать заданное качество продукции. Общее качество продукции улучшается, что подтверждается испытаниями и уровнем удовлетворенности клиентов.

Технологический интеллект

У нас нестабильно работало оборудование. Как это повлияло на производство? Мы использовали новые предложенные AI-режимы. Каков эффект?Партия не прошла контроль качества. Чем она отличается от других?Мы произвели на 1000 тонн больше. Как изменилась наша прибыль?