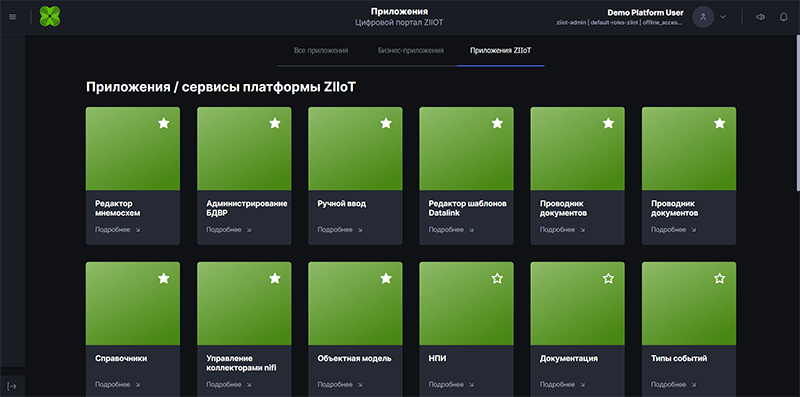

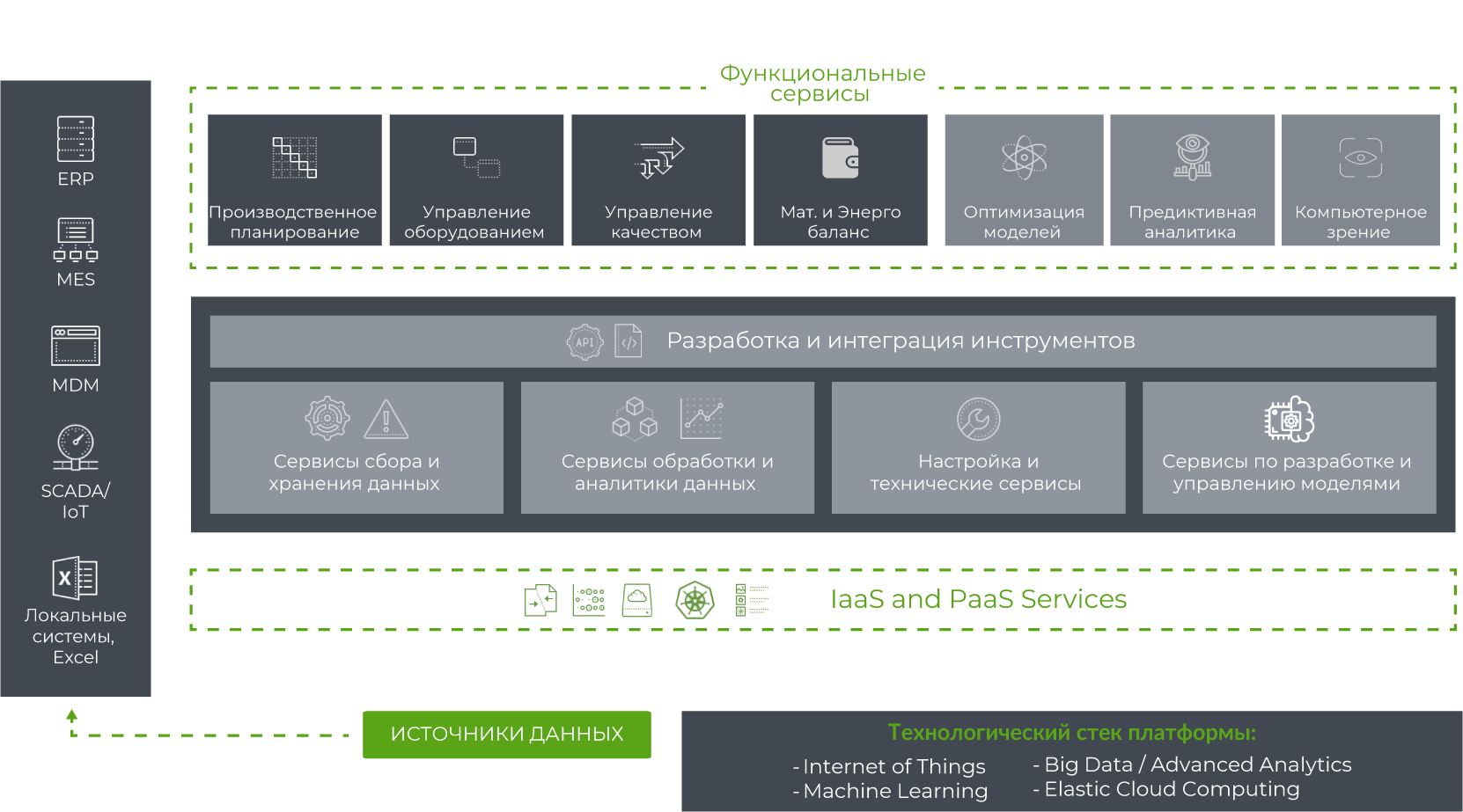

Обращаем внимание, что платформа ZIIoT это среда для быстрой разработки вертикальных IT-приложений, решающих конкретные производственные задачи.

При необходимости вы можете использовать её для разработки решений, заменяющих функционал решений зарубежных вендоров, приостанавливающих свою деятельность на территории РФ.

Зачем предприятия внедряют цифровую платформу?

Zyfra Industrial IoT Platform уже внедрена на многих промышленных предприятиях

Какие задачи помогает решать Zyfra Industrial IoT Platform

Крупным и средним

распределенным компаниям

распределенным компаниям

- Выстраивание процесса управления через единую систему

- Подготовка данных для AI и ML решений, создания цифровых двойников

- Обеспечение высокой скорости реагирования

- Интеграция существующих систем автоматизации в единый комплекс

- Снижение затрат на развитие и модернизацию ИТ-систем

- Обеспечение надежной системы безопасности

ИТ отделам промышленных компаний, ИТ-интеграторам

- Сокращение временных затрат на поддержание инфраструктуры

- Быстрое закрытие задач сопровождения, сокращение сроков решения локальных задач

- Инструментарий, включающий среду разработки, развертывания, тестирования, мониторинга

- Встраивание текущих наработок ИТ в современный ландшафт

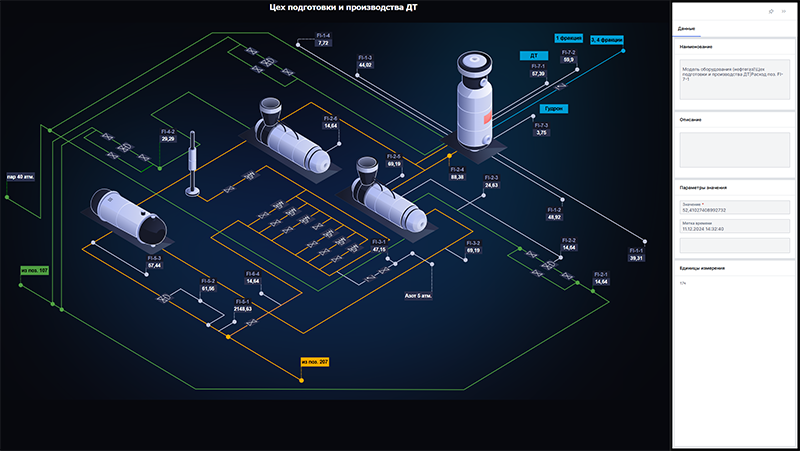

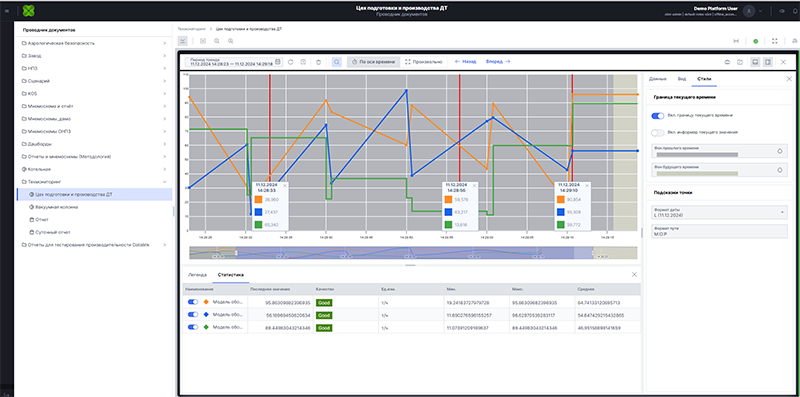

- Веб-инструментарий для разработки даш-бордов, мнемосхем и бизнес-графики

Отделам непрерывного совершенствования

- Обеспечение короткого цикла создания решений

- Переход от точечных задач к комплексному преобразованию

- Использование платформенных инструментов широким кругом пользователей

- Инфраструктура доступа к источникам данных

- Инструменты создания бизнес-приложений

- Интегрированные требования и система контроля

Функционал Zyfra Industrial IoT Platform

Платформа корпоративного уровня, предоставляющая все необходимые инструменты для управления жизненным циклом ИТ-системы

- 1Сбор, хранение и управление данными

- 2Среда для разработки корпоративных бизнес-приложений

- 3Сервисы администрирования и управления безопасностью

- 4Готовая платформа для оперативного развертывания, предоставляющая все необходимые инструменты для управления жизненным циклом ИТ-системы

Узнайте больше о возможностях

и функциях цифровой платформы —

скачайте брошюру.

и функциях цифровой платформы —

скачайте брошюру.

2000+

специалистов в сообществе разработчиков на базе ZIIoT

10ведущих российских промышленных компаний используют ZlloT

7партнеров

ИТ-интеграторов

ИТ-интеграторов

20реализованных

кейсов

кейсов

15текущих

пилотов

пилотов

15клиентских команд

используют ZlloT для

разработки продуктов

используют ZlloT для

разработки продуктов

5отраслевых дивизионов

Цифры разрабатывают

продукты на основе ZlloT

Цифры разрабатывают

продукты на основе ZlloT

Сервис и поддержка:

Техническая поддержка

Платформы и решений,

разработанных на платформе

Платформы и решений,

разработанных на платформе

Внедрение,

развертывание

развертывание

Курсы обучения для

специалистов внедрения

и разработки

специалистов внедрения

и разработки

Возможность оперативного внедрения цифровых

сервисов управления производством:

сервисов управления производством:

Производственная

аналитика и отчетность

аналитика и отчетность

Составление

производственного

расписания

производственного

расписания

Контроль

технологических

режимов

технологических

режимов

Планирование

и оптимизация

отгрузок

и оптимизация

отгрузок

Управление

балансами

балансами

Расчет коэффициента

использования

оборудования

использования

оборудования

Контроль

качества

качества

Бизнес-приложения

партнеров Zyfra

Marketplace

партнеров Zyfra

Marketplace

Почему выгодно разрабатывать приложения на Платформе ZIIOT

1

Публикация в маркетплейсе и легкий доступ к клиентам,у которых уже установлена Платформа ZIIOT

2

Все данные, которые нужны приложению собраны в одном месте,достаточно одной интеграции с Единой объектной моделью Платформы ZIIOT

3

Настроенный конвейер DevSecOpsсокращает время прохождения проверок безопасности

4

Быстрее установка и развёртывание на инфраструктуре клиентаза счёт встроенного в Платформу ZIIOT инсталлятора приложений

Почему платформы считаются цифровым будущим для промышленных индустрий?